References

Joint Group Projects

Stahlbau Nord GmbH

MEKO A200 Frigates

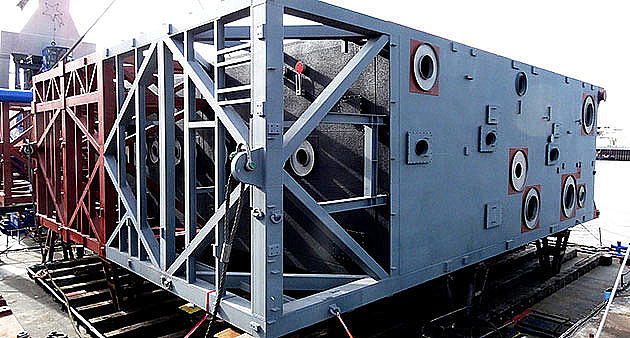

In 2017, Stahlbau Nord GmbH, in collaboration with project partners, fabricated the steel structure for the substation platform of the “Nordergründe” offshore wind farm, located approximately 15 kilometers east of the island of Wangerooge, in the estuary of the Weser River.

Due to the shallow water depth of only two to ten meters, the platform was constructed on a monopile foundation. The steel structure was manufactured at our facilities in Bremerhaven and Brake.

The “Nordergründe” offshore wind farm consists of 18 wind turbines, each with a capacity of 6.15 megawatts. The substation platform plays a central role in collecting and transmitting the generated energy to the onshore power grid.

SET Schiffbau- u. Entwicklungsgesellschaft Tangermünde mbH

Hybrid passenger ferries for Hamburg's ferry fleet

The SET Schiffbau- und Entwicklungsgesellschaft Tangermünde mbH built three modern hybrid ferries for use in the Port of Hamburg between 2023 and 2024: Neuland, Finkenwerder, and Grasbrook. These HADAG ferries were equipped at our Tangermünde site with an innovative plug-in hybrid propulsion system, complemented by a diesel range extender. This new propulsion technology reduces emissions by up to 70% and enables nearly silent, environmentally friendly operation. Each vessel measures approximately 33 meters in length, offers space for up to 250 passengers, and features optimized boarding areas—providing an efficient and comfortable solution for ferry operations on the River Elbe. The Neuland was successfully launched as the first vessel in the series in March 2024, followed by the Finkenwerder and the Grasbrook.

Lloyd Werft Bremerhaven GmbH

Mega-Yacht Solaris

Lloyd Werft Bremerhaven GmbH was involved in the construction of the expedition motor yacht “SOLARIS” from 2015 to 2021 – one of the largest and most technologically advanced yachts worldwide. With a length of 139.7 meters, a beam of 21.35 meters, and a draft of 5.95 meters, the yacht has a volume of 11,247 GT. The striking light gray hull with white superstructures is spanned by a distinctive, broad arch. This iconic design element connects both sides of the yacht and gives it a unique appearance.

BVT Bremen GmbH & Co. KG

Linde Cold Boxes

Since 2015, BVT Brenn- und Verformtechnik Bremen GmbH has been manufacturing several large components annually at its Bremen site in cooperation with BVT Chartering & Logistics for an industrial natural gas processing plant. The components produced are so-called “boxes” – steel-welded individual modules weighing around 130 tons and measuring approximately 20 meters in length. After production, these are transported by the floating cranes of BVT Chartering & Logistics to the Neustädter Hafen in Bremen. There, the modules are assembled into the complete system and undergo final outfitting before being integrated into an onshore natural gas processing facility as part of another heavy transport operation.

RSW Roßlauer Schiffswerft GmbH & Co. KG

Rebuilding the Wedtlenstedt Locks

The Wedtlenstedt Locks were rebuilt by RSW Roßlauer Schiffswerft GmbH & Co. KG from 2011 to 2012 in a collaboration with Stahlbau Dessau GmbH & Co. KG.

The lift gate mechanisms in the eastern lock were completely renewed. The old frame construction from 1938 was replaced with folding gates. And the existing rope drive of the gate was replaced with a chain drive.

RSW Roßlauer Schiffswerft GmbH & Co. KG

Rebuilding the Rostock Ferry Pier

The Rostock Ferry Pier was constructed from 2011 to 2012 in collaboration with Stahlbau Dessau GmbH & Co. KG and BVT Brenn- und Verformtechnik Bremen GmbH.

This was part of a “full service package” for the ferry pier measuring 37 meters in length and 28 meters in width and weighing in at approximately 1,000 t.

Stahlbau Nord GmbH

M/Y Luna

The M/Y LUNA was built in collaboration with EnPro Engineering und Produktionsgesellschaft mbH and RSW Roßlauer Schiffswerft GmbH & Co. KG.

The mega-yacht LUNA was built for a Russian owner. Stahlbau Nord GmbH constructed the hull out of steel and the deck superstructures out of steel and aluminum. The order included the production of the complete hull and partly outfitting of the vessel with fixtures. The individual sections were built at our sites in Bremerhaven and Brake. Additional sections were built by the HEINRICH RÖNNER GROUP in Bremen and Dessau-Roßlau.

SET Schiffsbau- u. Entwicklungsgesellschaft Tangermünde mbH

River Cruise Ship Viking Legend

The river cruise ship Viking Legend was built from 2008 to 2009 by SET Schiffsbau- u. Entwicklungsgesellschaft Tangermünde mbH in collaboration with BVT Brenn- und Verformtechnik Bremen GmbH and RSW Roßlauer Schiffswerft GmbH & Co. KG.

The vessel, which featured Scandinavian flair and innovative on-board technology, was built for Viking River Cruises Shipping Company. Owing to the capabilities of the shipyard, the hull was constructed in two parts and joined outside of the assembly halls. Thanks to the modern diesel-electric propulsion system, the vessel is extraordinarily quiet and environmentally friendly.